Sehr kleine und detaillierte Stickereien

In den letzten Jahren habe ich an sehr kleinen Stickmustern gearbeitet. Was mir in den 1980er und 1990er Jahren unmöglich erschien, wird jetzt möglich. Das liegt daran, dass Garnhersteller wie AMANN sehr dünne Garne hergestellt haben, die es ermöglichen, sehr kleine und detaillierte Stickereien zu realisieren. Es scheint einen regelrechten Wettbewerb unter Herstellern aus verschiedenen Branchen zu geben, wer auf einer Stickmaschine die kleinsten Buchstaben oder die detailliertesten Designs herstellen kann. Die Ergebnisse dieser Bemühungen waren sehr beeindruckend, darunter 1 mm hohe Buchstaben und daumengroße Stickereien mit hochfeinen Details. So interessant und schön das alles ist, es gibt Kritiker, die sagen, dies sei nicht die Realität; der Stoff, der bei den Demos verwendet wird, ist einer, auf dem jedes gestickte Muster großartig aussieht. Oder: Wie wird sich dieses Garn mit so kleinen Stichen und Feinheit unter Produktionsbedingungen bewähren? Der Realitätscheck!

1. Stoffarten berücksichtigen

Für Ihre Überlegungen, welche Stoffarten die beste Oberfläche für kleine oder detaillierte Stickmuster bieten, hier einige Vorschläge.

- Gewebte Stoffe wie für Arbeitsbekleidung, Hemden oder leichte Gewebe für Rucksäcke und Jacken

- Abzeichen - Materialien für Embleme

- Denim

- Softshell

2. Größe des Musters

Die Größe des Musters ist in erster Linie entscheidend für die Auswahl der richtigen Garnstärke.

3. Der Mustertyp

Ein komprimiertes Muster, bei dem die Designelemente weit auseinander liegen. Feine dünne Details, Schriftart, Schrift, Block, Serife oder Buchstaben mit dicken, dünnen Balken, um nur einige zu nennen. Überprüfen Sie die oben genannten 3 Punkte, bevor Sie mit der Digitalisierung des Musters beginnen. Dies hilft bei der Wahl der richtigen Garnstärke und den Musteranpassungen, die vorgenommen werden müssen, damit es sich für die Stickerei eignet. Unten finden Sie einen Überblick über die Produktlinie Serafil von AMANN.

Je dünner das Garn, desto mehr Stiche müssen Sie ausführen. Überlegen Sie sich also, welche Garnstärke Ihnen die optimale Deckung bietet, ohne auf zu viele Details verzichten zu müssen. In einigen Fällen wäre dies das Serafil Etikett Nr. 60. Wenn Sie sehen, dass die Details nicht ausreichend definiert sind, dann kommt als nächstes das Serafil Fine Etikett Nr. 75 in Frage. Bei diesen beiden Garnstärken sollte die Breite des Plattstiches mindestens 1 mm betragen, um ein qualitativ hochwertiges Ergebnis zu erzielen. Das Serafil Feinstich Etikett 100 eignet sich perfekt für die Herstellung superfeiner Stickdetails. Die Betonung liegt auf den Worten SUPER FINE. Mit dieser Garnstärke können Sie Satinbarren von weniger als 1 mm Breite oder laufende Linien, die kleine integrierte Designs bilden, herstellen.

Es gibt keine wirklichen Einschränkungen oder Regeln, die besagen, dass Sie diese spezielle Garnstärke für dieses oder jenes Design und diese oder jene Mustergröße verwenden müssen. Dieser Artikel soll Ihnen lediglich als Entscheidungshilfe dienen. Sie werden selbst herausfinden, was für Ihr Stickprojekt funktioniert oder nicht funktioniert. Wie bei den meisten Dingen in der Stickerei ist es am Anfang immer Versuch und Irrtum, bis Sie sich zurechtfinden. Jedes Stickprojekt ist eine neue Herausforderung.

Einige Tipps zum Digitalisieren besonders feiner Garnstärken.

Serafil fine ist eine von AMANN. hergestellte Garnserie. Es gibt drei Garnstärken, aus denen Sie wählen können:

- 100% Polyester Multifilament

- Farbpalette: 100

- Eticket 120/2 entspricht Garnstärke # 60

- Eticket 200/2 entspricht Garnstärke # 75

- Eticket 300/2 entspricht Garnstärke # 100

Anwendung:

- für feinste Details und kleinste Beschriftungen bis zu 1,5 mm Schrift

- zum Befestigen von Pailetten (anstelle von kratzendem Nylonfaden)

Nadelstärke:

- DBxK5 Nm 60 – 65

- DB x 1 Nm 55 (Singer Nummern können abweichen)

4. Aufschlüsselung der Stichdistanz

So könnte eine Stichdistanz aussehen. Serafil fine Etikett 60-Stich-Abstand 3,0 bis 2,5 = 1/10 mm nicht empfohlen, tiefer zu gehen. Serafil fine Eticket 75-Stich-Abstand 2,5 bis 2,0 = 1/10 mm. Es wird nicht empfohlen, tiefer zu gehen, aber in einigen Fällen bis zu 3,0. Serafil fine Ticket 100 Stichabstand 2,0 bis 1,0 = 1/10 mm 1,0 dies ist die Grenze, kann aber in einigen Fällen bis zu 3,0 betragen. Die oben aufgeführten Stichabstände sind relativ. Bei größeren Formen kann die volle Stichdistanz angewendet werden. Je kleiner und schmaler die Form, desto weniger Stiche werden benötigt, da nicht genug Platz dafür vorhanden ist.

5. Unterlegungsstiche

Unterlegungsstiche sind die Stiche, die unter die oberen Stiche gelegt werden. Der Unterleger bewirkt zweierlei; er verbindet den Steppstich mit dem Untergrund, wodurch ein Verschieben des Stoffes verhindert wird. Zusätzlich stabilisiert er die Steppstiche und verhindert ein Verziehen beim Sticken. Für ein optimales Ergebnis bedeutet dies, dass Sie selbst auf dem dünnsten Satinstich unter 1 mm mindestens eine einzige Reihe von Laufstichen platzieren sollten. Einbindestiche und Steppstiche müssen mit Sorgfalt platziert werden. Die Standardstiche sind zu gross und erzeugen Knoten. Beim Digitalisieren von kleinem, dünnem Satin werden Einbindestiche zum Aufnehmen des Unterfadens verwendet. Bei Buchstaben oder anderen Elementen ist es ratsam, mit kleinen manuellen Stichen zu beginnen, als ob Sie eine laufende Linie digitalisieren würden.

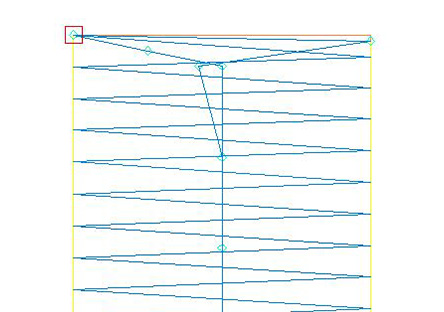

Muster einer Plattstichspalte und eines Linienunterlegers durch die Mitte der Säule

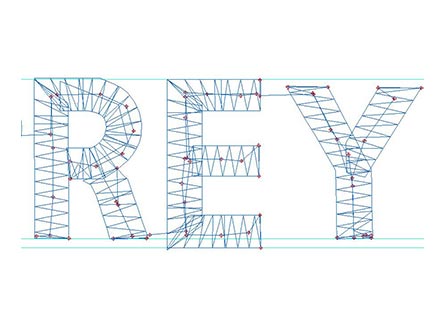

Diese Art der Unterlage ist auch bei sehr kleinen Buchstaben äußerst wichtig, wie das Beispiel der Buchstaben R,E,Y zeigt. Diese Buchstaben sind 3 mm groß.

Beispiel für die Digitalisierung von Daten aus Software.

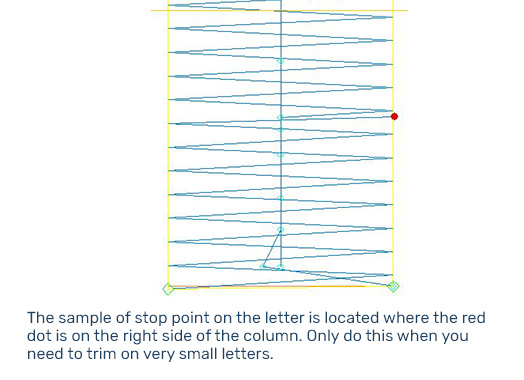

Beginnen Sie beim Digitalisieren einer kleinen Grafik an einer Stelle, an der die Einbindestiche mehr Platz haben, als Sie für die normalen Einbindeformen verwenden können. Bei sehr kleinen Segmenten versuche ich, den Steppstich zu vermeiden. Wenn das nicht möglich ist, haben Sie nur die Möglichkeit, ein oder zwei Stiche zu setzen, um das Ende der Naht zu fixieren. Einige Stickerinnen ziehen es vor, zwischen den Buchstaben von Hand zu schneiden, anstatt den Fadenschneider der Maschine zu verwenden. Dies geschieht, wenn die Buchstaben so klein sind, dass die Maschine keine Geschwindigkeit aufnehmen kann, bevor der Buchstabe fertig ist. Beim Schneiden auf der Maschine an der Stelle, an der es abgeschnitten wird, zieht sich der Faden auf die Rückseite des bestickten Stoffes zurück. Bei sehr kleinen Buchstaben kann dies zu Verzerrungen führen, vor allem wenn Sie am unteren oder oberen Ende eines Buchstabens enden. Um dies zu vermeiden, machen Sie die Fixierstiche einige Stiche höher auf der Satinleiste. Am besten ist es, sie danach von Hand auszuschneiden.

6. Kleine Muster und Buchstaben auf Strick, Pique

In den meisten Fällen ist Strick nicht das beste Basismaterial für kleine Logos oder Designs. Es gibt einige Ausnahmen, aber es ist schwierig, es richtig hinzubekommen. Die Ausnahme wäre ein sehr kompaktes Design. Hier kann eine Garnstärke von Ticket 75 verwendet werden. Kleine Schriftzüge werden in den meisten Fällen einsinken und verschwinden. Bei texturierten Oberflächen müsste ein wasserlöslicher Belag verwendet werden, damit die Fadenstiche nicht in den Stoff einsinken.

7. Garnspulen

Je dicker die Garnspule (Unterfaden), desto ausgeprägter ist die Absteppung. Ein dickerer Unterfaden wie ein Saba 120 oder 150 kann helfen, den dünneren Oberfaden auf dem Stoff zu halten. Dies ist akzeptabel, wenn die Stickerei auf einen dicken Stoff oder ein Piqué-Gestrick genäht wird. Die ISABOB 190 ist die richtige Wahl, wenn auf feinen, dünneren Stoffen gestickt wird. Hier sind die dickeren Spulengrößen nicht zu empfehlen. Die dünnere Spule hält die Stickerei fein und nicht sperrig.

8. Ein Muss - die richtigen Nadeln, Nadelspitzen und die richtige Fadenspannung

Die dünneren Garnstärken erfordern kleinere Nadelstärken #65 bis #55. In den meisten Fällen funktioniert eine RG-Spitze für die meisten Webstoffe und eine FFG-Spitze für Strickwaren.

9. Fadenspannung

Dies hängt davon ab, wie straff Sie Ihre Maschinenspannung normalerweise betreiben. In den meisten Fällen müssen Sie die oberen Spannungen etwas lockern, aber nicht sehr viel. Nehmen Sie erste kleine Anpassungen der Spannung vor, während Sie sticken. Mit zunehmender Erfahrung werden Sie lernen, wie Ihre Maschine mit der Fadenspannung arbeitet.

10. Unterlagen

Wenn Sie glauben, alles richtig gemacht zu haben, und das Ergebnis immer noch nicht akzeptabel ist, dann könnte es an der verwendeten Unterleger liegen. Besser ist es, dehnbare Materialien mit einem Schneidevließ zu besticken, denn das Vlies hält die Stickerei auch nach dem Waschen an Ort und Stelle. Verwenden Sie für den gewebten Stoff eine Unterlage, die abgerissen werden kann. Probleme können auftreten, wenn Sie mehrere Lagen oder sehr dicke Vliese verwenden. Dann wird die Stickerei hart und sperrig. Dünnere Stoffe benötigen ein leichteres Vlies, aber das Vlies sollte nicht perforieren. Wenn er während des Stickens perforiert, kommt es höchstwahrscheinlich zu Stoffbewegungen, die auch dann stattfinden, wenn man sie mit dem Auge nicht sehen kann. Tipp: Stickerei-Klebespray hilft, den Stoff besser mit dem Vlies zu verbinden. Ich finde das wichtig, wenn man mit kleinen Motiven arbeitet.

11. Maschinengeschwindigkeit

Die Designs, die mit diesen dünneren Fadengewichten hergestellt werden, sind normalerweise superklein, so dass eine Verlangsamung der Maschine auf 700 Stiche pro Minute dazu beiträgt, dass die dünnere Nadel nicht zu stark schwingt. Die Designs sind normalerweise klein, daher ist die Laufzeit nicht lang.

12. Reinigung

Musteroptimierung oder auch Reinigung genannt. Dies ist das Wichtigste!

Prüfen Sie, ob die Reinigungsoption auf der Maschine aktiviert ist, in den meisten Fällen ist sie das. Hier müssen Sie die Einstellung ändern oder sie ausschalten. Wenn Sie dies nicht tun, werden Sie sehen, dass sich die Stichzahl verringert, wenn das Muster in die Maschine geladen wird. Das bedeutet, dass Stiche gelöscht werden. Wenn die Reinigung auf 0,5 mm eingestellt ist, werden alle Stiche dieser Größe und kleiner vom System gelöscht. Man sagt, kleine Stiche sind nicht gut für die Stickerei, aber nicht bei der Arbeit mit dünneren Fadengewichten.

Ich genieße die Herausforderung, kleine Stickereien zu kreieren, nachdem ich jahrelang mit der Standard-Garnstärke 40 gearbeitet habe. Die Verwendung des richtigen Fadens und dünnerer Gewichte hat einen großen Unterschied gemacht.