THE PERFECT SEAM

Sewing and Embroidery Solutions for Automotive and Interior

ZSK - THE PERFECT SEAM

INNOVATIVE SEWING AND EMBROIDERY SOLUTIONS

For decades, sewing and embroidery required separate equipment. ZSK as a manufacturer with a rich history and reputation in the field of durable embroidery machines now integrates both processes into one.

ZSK solutions handle fabrics, artificial leather, alcantara and leather, even those laminated on foam or spacer fabric, enabling impressive 3D effects.

The Vision System ensures precise alignment for sewing, embroidery, and perforation, accommodating material shrinkage.

ZSK supports efficient processes with in-house production of tools, supports the design development process and sample production. From initial concept to automated production, ZSK is your dedicated partner throughout.

APPLICATIONS

ZSK sewing and embroidery solutions are covering a whole range of interior applications

- Seats

- Headrests

- Door/floor mats

- Door panels

- Roof liner

- Accessories

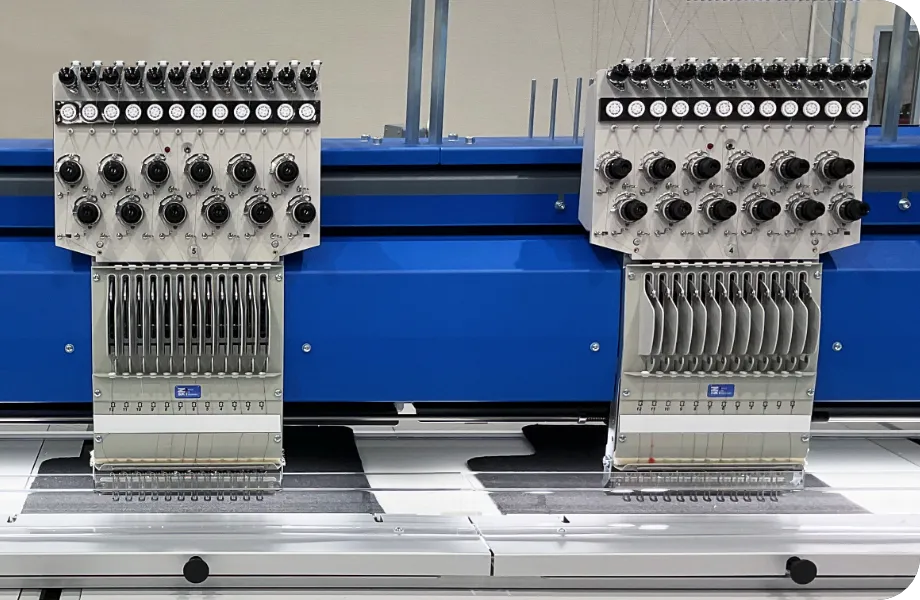

POPULAR MACHINE MODELS

RACER 0124-1000 (700)

|

No. of Heads | Needles |

1 | 24 |

|

Head Distance: |

- |

|

Max. Embroidery Field Width |

1.000 mm / 39,4" |

|

Max. Embroidery Field Depth: |

700 mm / 27,6" |

|

Max. Speed: |

1.000 rpm |

|

Machine Measurements WxDxH: |

2.580x1.840x1.790 mm |

RACER 1XL

|

No. of Heads | Needles |

1 | 24 |

|

Head Distance: |

- |

|

Max. Embroidery Field Width |

650 mm / 25,6" |

|

Max. Embroidery Field Depth: |

700 mm / 27,6" |

|

Max. Speed: |

1.000 rpm |

|

Machine Measurements WxDxH: |

1.960x1.825x1.790 mm |

RACER 0224-700D (700)

|

No. of Heads | Needles |

2 | 24 |

|

Head Distance: |

700 mm / 27,6" |

|

Max. Embroidery Field Width |

700/1.400 mm / 39,4" / 78,8" |

|

Max. Embroidery Field Depth: |

700 mm / 27,6" |

|

Max. Speed: |

1.000 rpm |

|

Machine Measurements WxDxH: |

3.380x1.840x1.760 mm |

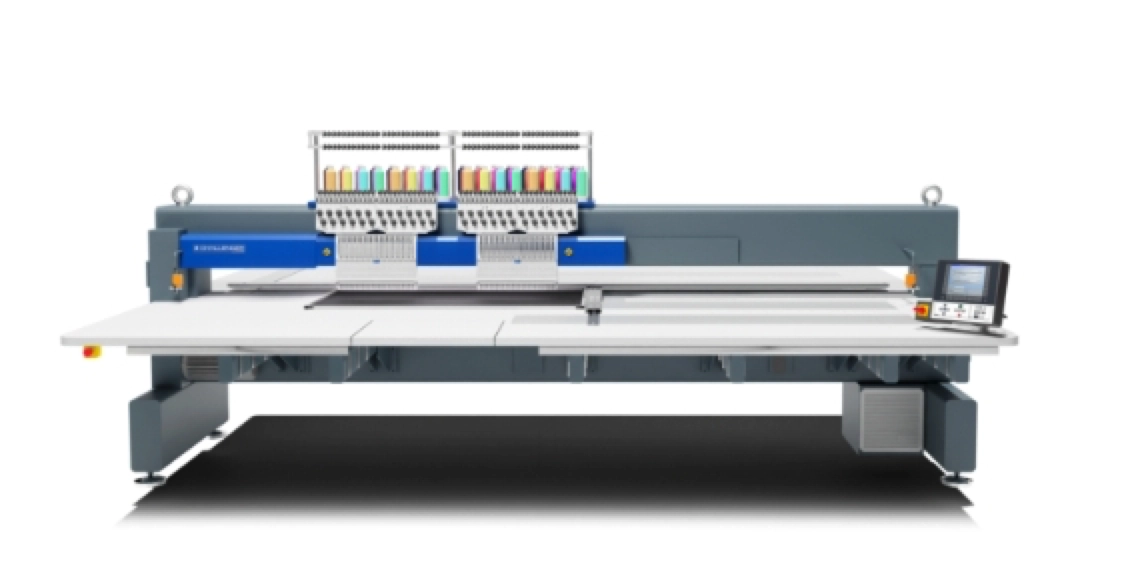

CHALLENGER SGF 0224-700D (1000)

|

No. of Heads | Needles |

2 | 24 |

|

Head Distance: |

700 mm / 39,4" |

|

Max. Embroidery Field Width |

700/1.400 mm / 39,4" / 78,8" |

|

Max. Embroidery Field Depth: |

1.000 mm / 39,4" |

|

Max. Speed: |

1.000 rpm |

|

Machine Measurements WxDxH: |

4.100x2.460x1.660 mm |

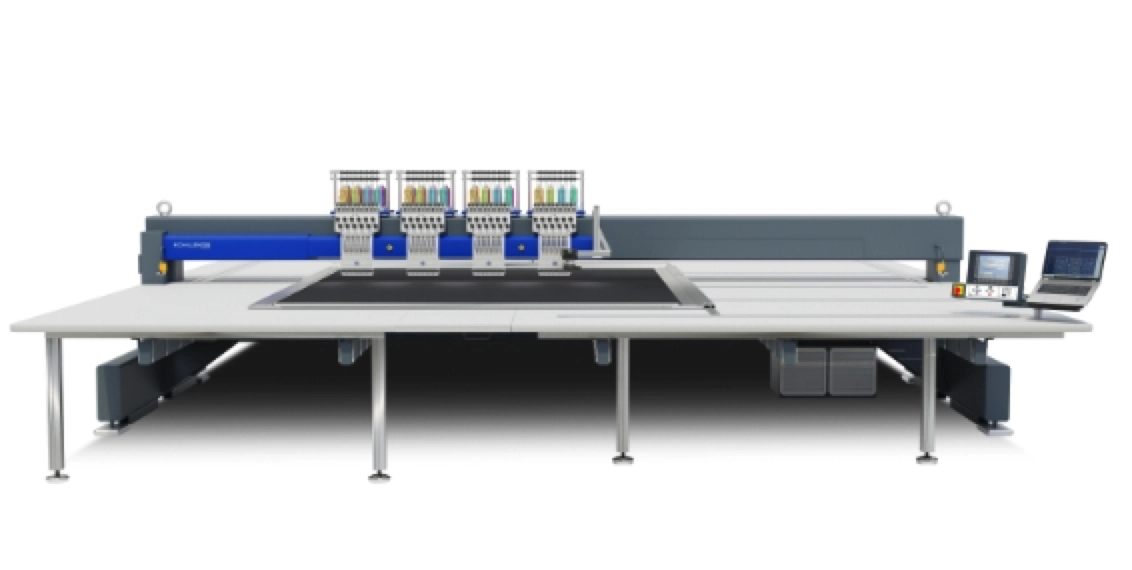

CHALLENGER MCF 0412-450Q (2500)

|

No. of Heads | Needles |

4 | 12 |

|

Head Distance: |

450 |

|

Max. Embroidery Field Width |

450; 900; 1.350; 1.800; 2100 mm |

|

Max. Embroidery Field Depth: |

2.500 mm / 98,5" |

|

Max. Speed: |

1.000 rpm |

|

Machine Measurements WxDxH: |

5.690x5.460x1.640 mm |

Machine Setup

Technical Specification

ZSK offers +/- 150 available machine models with a variety of head distances, needles or embroidery field sizes. Customer specific models can be developed upon request. Various table plate designs are available to ensure optimal operating or service access, especially for large embroidery field depths.

| No. of Heads | up to 56 |

| No. of needles per head | 6, 9, 12, 18 or 24 |

| Size of thread | 15 - 210 tex |

| Thread type | Sewing and embroidery thread |

| Material thicknesses | up to 20 mm |

| Sewing field size | up to 1.400 x 700 mm on RACER up to 2.100 x 2.500 mm on CHALLENGER |

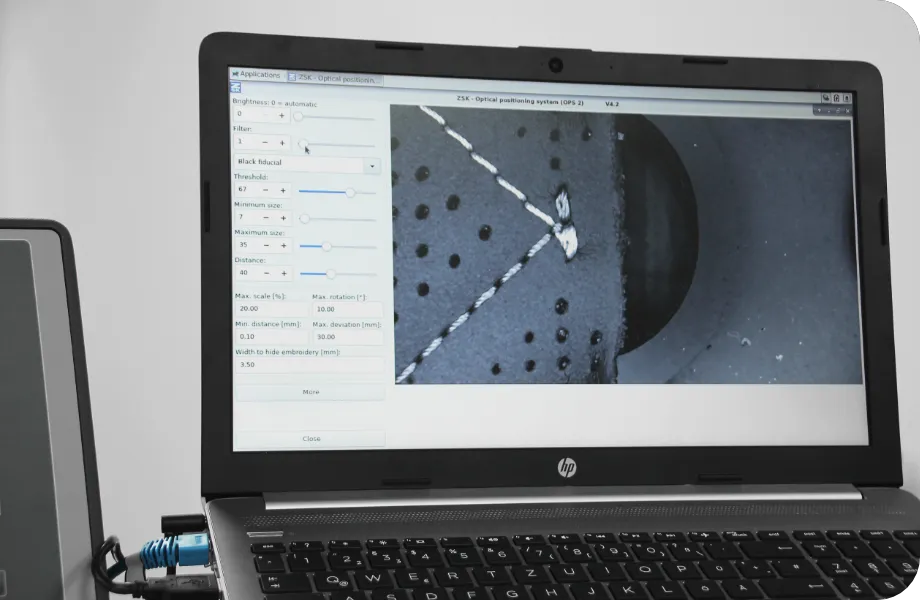

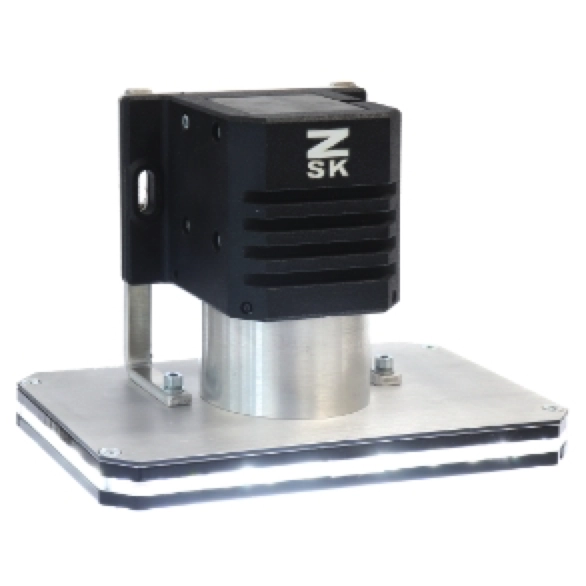

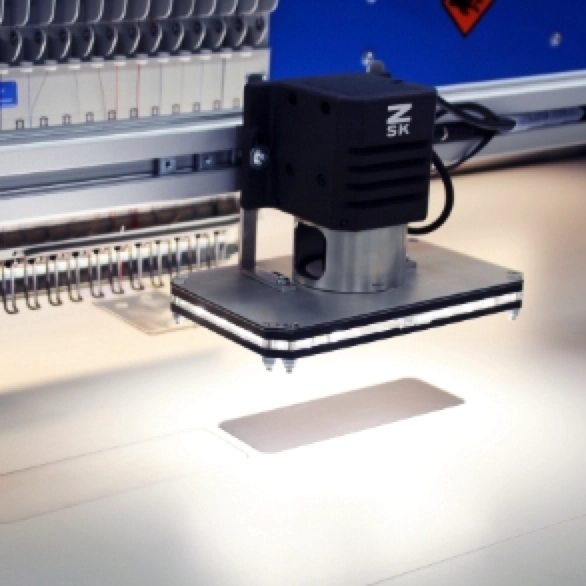

VISION SYSTEM

PRECISION IS KEY

The also called Optical Positioning System (OPSII) is a camera based system which is needed for perforated leather/fabric (e.g. Alcantara, artifical leather) cut parts to guarentee precise placement of sewing lines/decorative elements within the perforation gaps.

The system compensates the deviation caused by the lamination, perforation as well as sewing process. For this purpose a variance analysis is made between the inital CAD file and the final cut part. Within a fraction of seconds the software recalculates the position of the sewing lines/decorative elements. This includes enlarging, downsizing and rotation.

Besides perforation the system also detects embossed, welded or printed effects on leather/fabric.

Depending on customer needs we are offering two software versions of the Vision System:

Standard and Advanced

STANDARD

COMMON FEATURES

- Applicable for perforation, embossing, welding and print on leather and fabric

- Up to 10 scan points per sewing line/decorative element

- Regocnition of different hole sizes and shapes

- Detection of different colours

- Adjustable to different material heights

- Easy QR-code creation of each design for efficient production

ADVANCED

ADVANCED ADD ONS

EDGE DETECTION

Edge detection ensures exact positioning of the back-tacks independent from cut part tolerances by measuring the size of the cut part with the first and last scan point at the cut part edges.

Positive or negative notches on the cut part do not cause an issue since there are special filter settings for notches.

Edge detection is a unique feature by ZSK which solves the issues of misaligned back-tacks caused by tolerances in the pre-processes.

In this context the software reduces the scrap rate as well as downtimes of the machine. Recommended e.g. for production with fine cuts.

VERIFICATION SIZE OF DESIGN VS. FRAME

Before the machine starts to operate the software reviews if the recalculated design still fits to the frame. This avoids machine damages and decreases down times.

SELECTION OF HOLE COLOUR

Improved contrast settings between the leather/fabric colour and the colour of the perforation holes. This allows a considerable relief for working with fabrics like e.g. Alcantara, Dinamica a nd Suede.

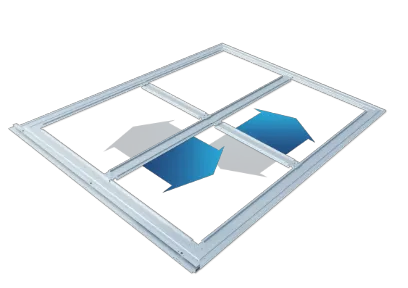

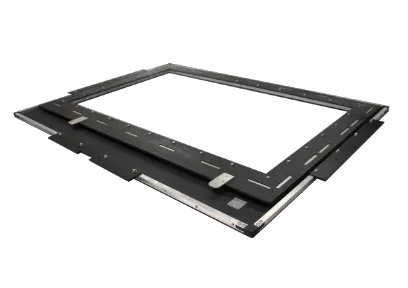

FRAME SOLUTIONS

PRECISION IS KEY

At ZSK, we boast our own frame shop floor where every aspect of design, construction, and manufacturing is handled in-house.

This enables us to tailor our machines and equipment to meet your specific needs and project requirements.

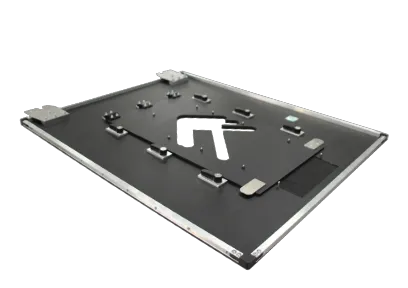

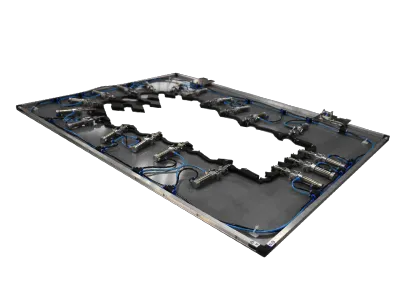

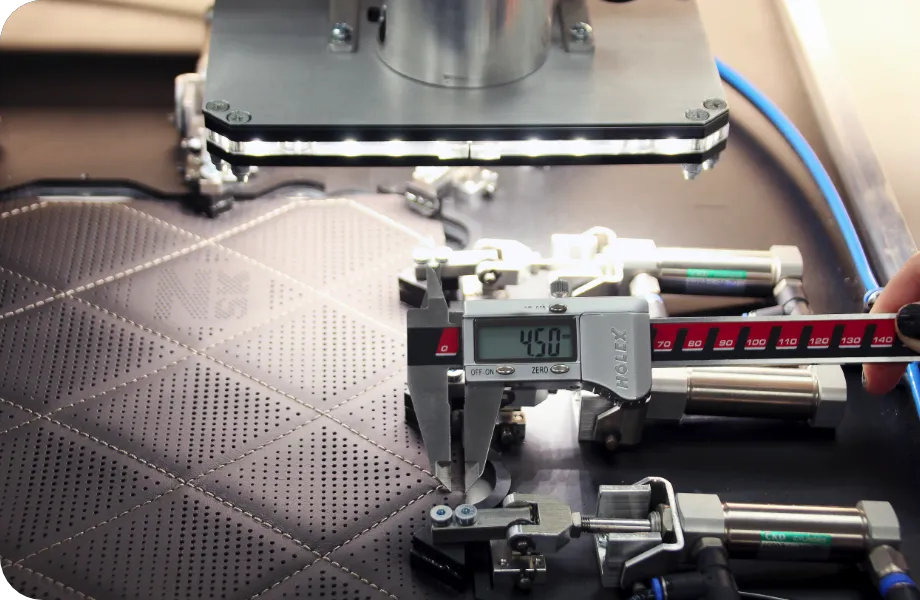

EMBROIDERING FLOOR MATS

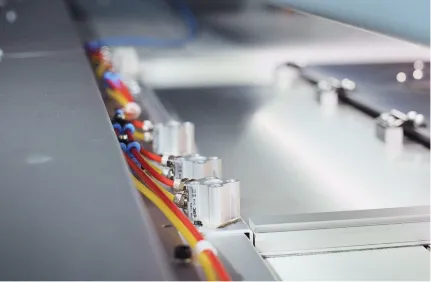

FLOOR MAT TENSIONING

FLEXIBILITY

Floor mats can be enhanced with high-quality embroidery. ZSK provides the appropriate equipment for this. The displayed pneumatic floor mat tensioning enables effortless clamping.

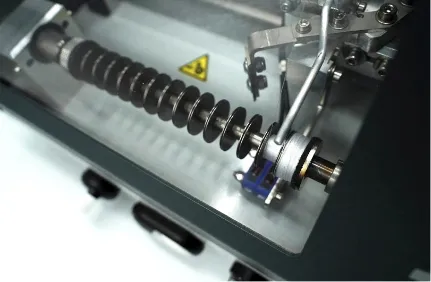

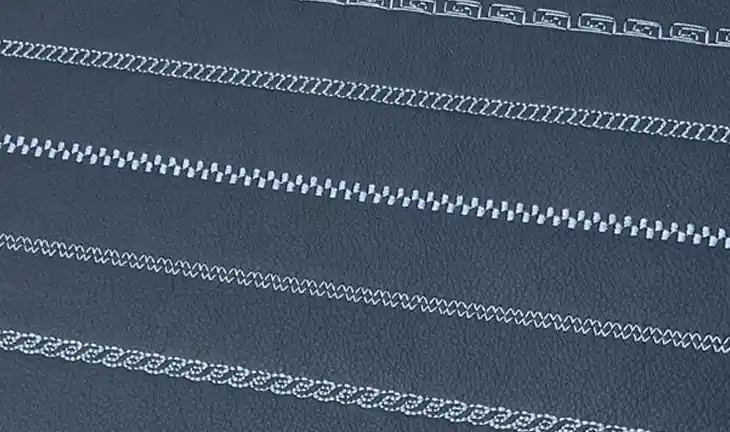

EMBROIDERING DECORATIVE SEAMS

DECORATIVE SEAMS

PRECISION

- Utilize countless pre-installed decorative stitches in EPCwin.

- Create your own decorative stitches and enjoy limitless design freedom.

OPTIONEN

OPTIONEN VISION SYSTEM

T8 AND LAPTOP MOUNT

STANDARD & ADVANCED

- Modular mounting system for T8 and vision system laptop

- Easy operation and improved design monitoring for the operator

CAMERA PROTECTION

STANDARD

- Prevents the lid from hitting the camera when opened

- Reduces recalibration of the camera because of mechanical shocks

RINGLIGHT PREMIUM

ADVANCED

- Enlarged lightfield

- Mandatory for use of edge detection

TABLE PLATE INSERTS

ADVANCED

- Enhanced recognition of different leather colours

- Mandatory for use of edge detection

ACCESSORIES

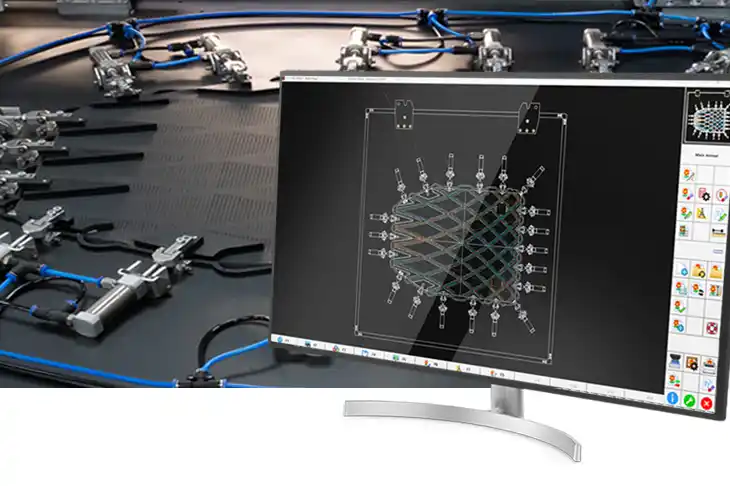

EPCwin CAD SOFTWARE

OPTIONS VISION SYSTEM

Use EPCwin for all production steps and also crea- te your vector files with the fully integrated CAD drawing mode.

HIGHEST PRECISION

EPCwin 7 is outstanding in terms of precise stitch calculation. With adjustable stitch limitation, angle settings and stitch filters, each design can be con- trolled stitch by stitch with an accuracy of 0.1mm.

HOW DOES IT SUPPORT YOU?

- Decorative seams

- Creation of your own Stitch Patterns

- Supports export format for Vision System including edge detection

OPTIMAL MACHINE CONTROL

EPCwin offers a seamless workflow and full ma- chine control through a direct connection to your ZSK machine solution. This also improves produc- tion efficiency and embroidery quality.

COLLABORATIVE WORK ON PROJECTS

With EPCwin, files or parameters can be perfectly organized and shared for a constant and traceable workflow.

SUPPORT

SERVICE

ZSK supports from the first design idea up to serial production.

- Design development

- Design and production of frames

- Feasibility studies

- Prototyping

- Time studies

- Production of pilot series

- Production until machines are out for delivery

- FAT (factory acceptance test)

- SOP (start of production)

- Software/machine and application training