Beyond Embroidery – How ZSK Embroidery Machines Are Revolutionizing Custom Quilting

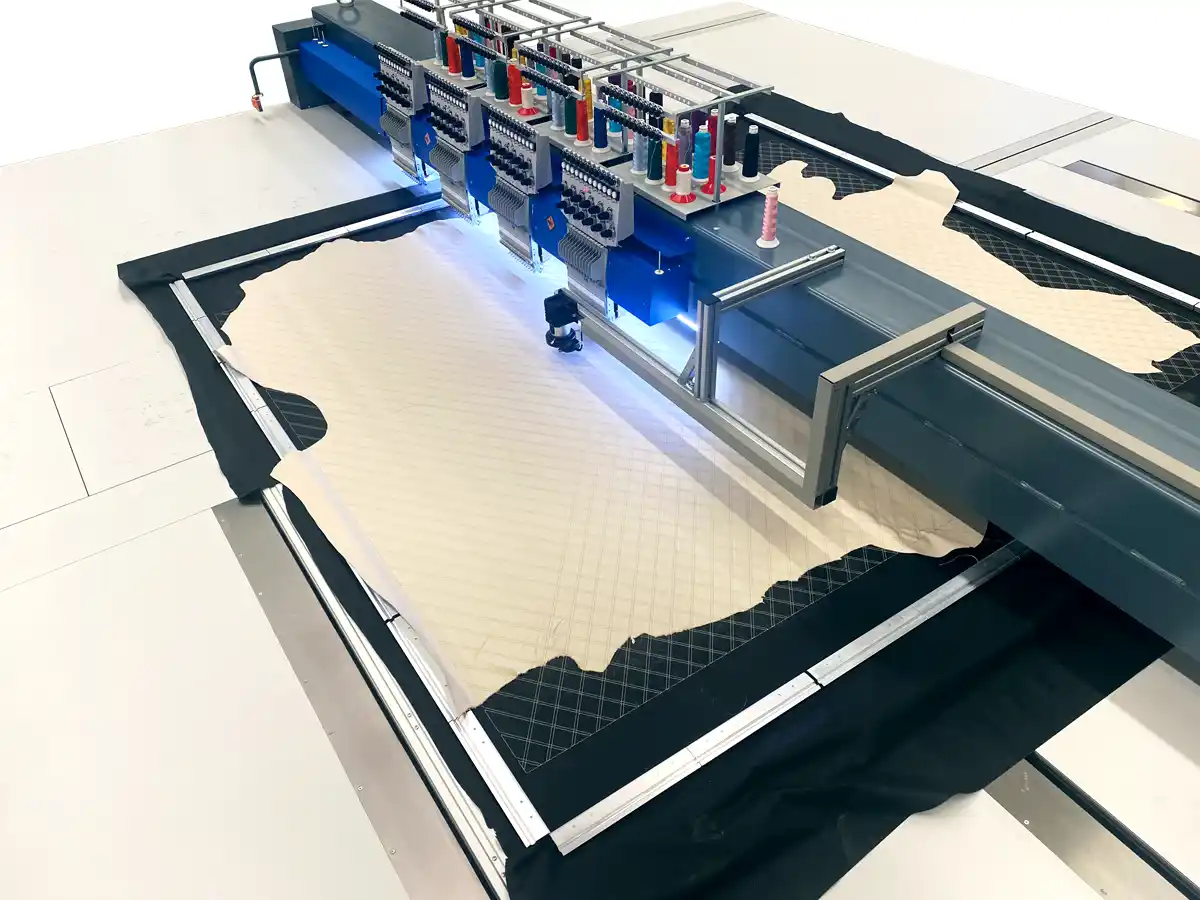

Featuring the ZSK CMCF 0412-450Q for Large-Scale Quilted Creations

In the world of textile craftsmanship, quilting is experiencing a revival—driven not only by traditional artisanship but increasingly by automation and customization. One technology stands out in this transformation: industrial embroidery machines.

While known for precision embroidery, ZSK’s modular systems are now making waves in the custom quilting sector—offering flexibility, scale, and unmatched design possibilities.

At the Heart: The ZSK CMCF 0412-450Q

This high-precision embroidery system is adapted specifically for large-format quilting. With a working field of up to 2,100 x 2,500 mm—and an extended option up to 2,100 x 3,000 mm—the CMCF 0412-450Q redefines what is technically and creatively possible for quilt producers.

Why Use an Embroidery Machine for Quilting?

- Precision: Each stitch can be placed with pinpoint accuracy—ideal for complex patterns, textures, or layering effects.

- Design Freedom: With embroidery software, digital quilting patterns can be created, edited, and scaled with ease.

- Automated Consistency: Unlike free-motion quilting, embroidery quilting offers consistent results—crucial for batch production or premium finishes.

- Speed & Efficiency: With multi-needle heads and automated control, production is significantly faster than manual or long-arm quilting methods.

- Mixed-Media Potential: Embroidery machines can combine quilting with text, logos, or technical embroidery for smart textiles and functional layers.

The Business Case for Custom Quilts

Custom quilts are no longer niche—today, they serve as:

- High-margin personalized gifts

- Branded hospitality or interior design solutions

- Artist collaborations and limited editions

- Wellness and therapy blankets with aesthetic and sensory appeal

- Functional textiles (e.g., thermal, acoustic, or pressure-sensitive quilts)

The demand for individualization and small-batch runs is growing rapidly. With the ZSK system, quilt producers can move away from manual, time-intensive production and embrace on-demand quilting with digital repeatability.

CMCF 0412-450Q: Built for Quilting at Scale

- Large Embroidery Field: Up to 2.1 x 2.5 m (or 2.1 x 3.0 m) per frame, ideal for full bed-size quilts without fabric realignment.

- Reduced Shifting/Registration Errors: Compared to pull-through systems, the static frame setup ensures perfect alignment—especially on multi-layered or high-loft quilts.

- Multi-head Capability: For production scenarios, multiple heads can be configured for parallel operation or custom sequencing.

- Roll-to-Roll Production Support: ZSK enables continuous quilting workflows, ideal for edge-to-edge patterns, textile art panels, or industrial applications.

- Easy Material Handling: With adjustable frame tensioning and heavy-duty clamp options, even thicker quilt sandwiches can be handled effortlessly.

From Creative Studio to Scalable Business

Whether you’re an artist scaling your custom quilt business or a manufacturer looking to tap into new personalization markets, ZSK’s embroidery-based quilting offers an exceptional blend of creativity and productivity.

Custom quilting with ZSK means fewer limitations, more consistency, and a platform that grows with your imagination.

About CMCF 0412‐450 Q (2500)

The CMCF 0412‐450 Q (2500) is an embroidery machine with four embroidery heads that can embroider and sew up to four workpieces at the same time. The smallest embroidery field width is 450mm, the maximum width is 2,100mm.

This means that an area of up to 5.25m2 can be processed in a single operation.

Technical Data

| Embroidery Heads | 4 |

|---|---|

| Colours per Head | 12 |

| Head Distance [mm] | 450 |

| Embroidery Field Width max.[mm] | 450 / 900 / 1.350 / 1.800 / 2.100 |

| Embroidery Field Depth max. [mm] | 2.500 |

| Embroidery Speed max. [U/min] | 1.000 |

Subscribe to Newsletter

Contact