What Type Are You: Inside or Outside?

ZSK STICKMASCHINEN is known for first-class machinery and excellent service – but did you know our mission extends far beyond just hardware?

With our specialized divisions for technical embroidery – 3E Smart Solutions and Unwind3D – we support your innovations. We're by your side: from the initial idea to a market-ready product.

Whether you aim to develop **Smart Textiles, E-Textiles**, or **composite solutions**: We bring the necessary know-how, the right tools, and comprehensive services. This is how we transform embroidery into intelligent, functional products.

The ZSK Laying Motor: Your Key to Precision

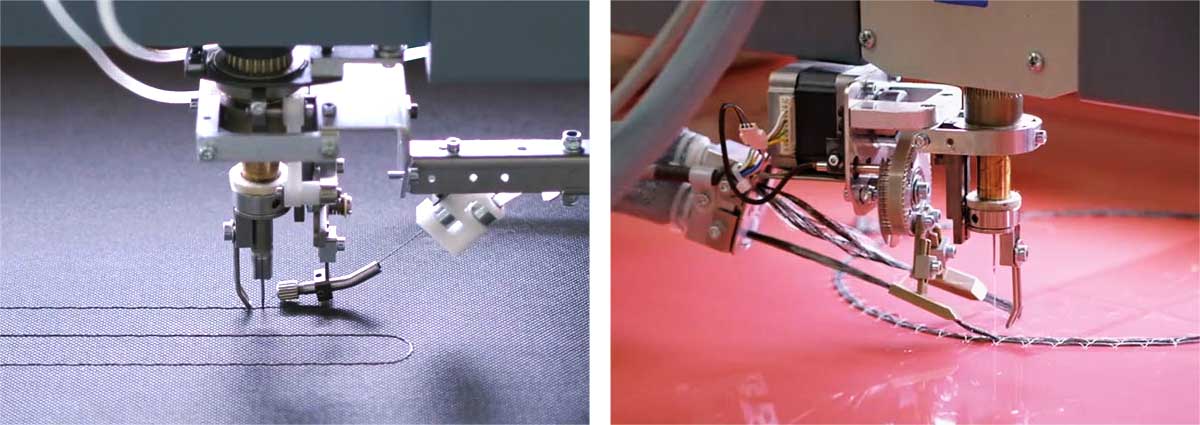

To unlock the full potential of your ZSK embroidery machine and optimize your processes, a crucial choice awaits: the right Laying Motor. At ZSK, we offer two variants of the ZSK Laying Motor, both developed for high-precision fiber placement in technical embroidery. Both deliver outstanding laying quality, but their differences can significantly impact your workflow.

The Laying Motor is your assistant when it comes to precisely positioning fibers, wires, tubes, or cables. The attachment of these materials to the base fabric is done via a **precise zigzag stitch**. Whether you're active in the automotive, aerospace, medical, or wearables industries: This motor is indispensable for our Tailored Fiber, Wire, or Tube Placement (TFP/TWP) technology.

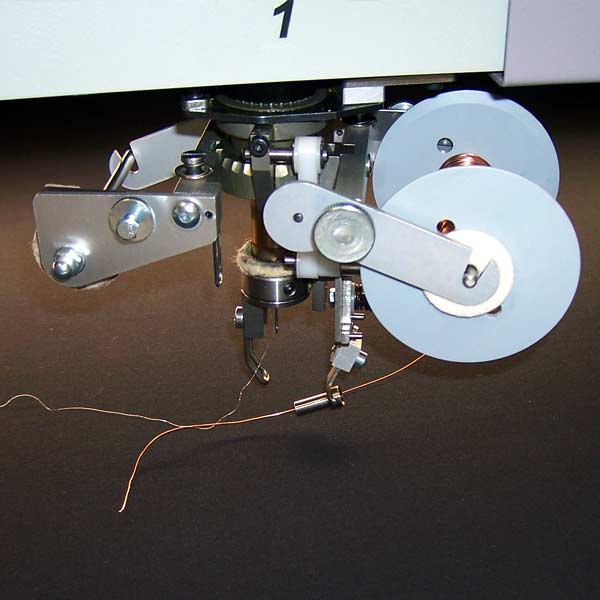

The Inside Laying Motor: The Smart Partner for Your Development

Ideal for Research and Development

Are you an Explorer Type?

Then the Inside Laying Motor is perfect for you. It's the cost-efficient choice, especially if you focus on prototyping and innovative development.

What Makes it the Ideal Development Partner

- **Entry-Friendly:** Lower acquisition costs that make it easier for you to get started.

- **Versatility in Material Feed:** Compatible with Single/Twin Fiber/Wire Supply and Active Supply System, adapting to your needs.

- **Optimal for Small Spools:** Allows for embroidering ribbons and utilizing the winding function for special details.

- **Fast Fiber Laying:** Ideal for quickly conducting your experiments and tests.

- **HV-TFP Suitability:** Perfectly suited for processing fibers and wires.

Important Points to Consider

- **Manual Material Changes:** If you frequently need to change materials, more manual work is required, which can slow down the workflow.

- **No Automatic Cutter:** Fibers and wires must be cut manually.

- **Maintenance Access:** Access for maintenance is somewhat more challenging.

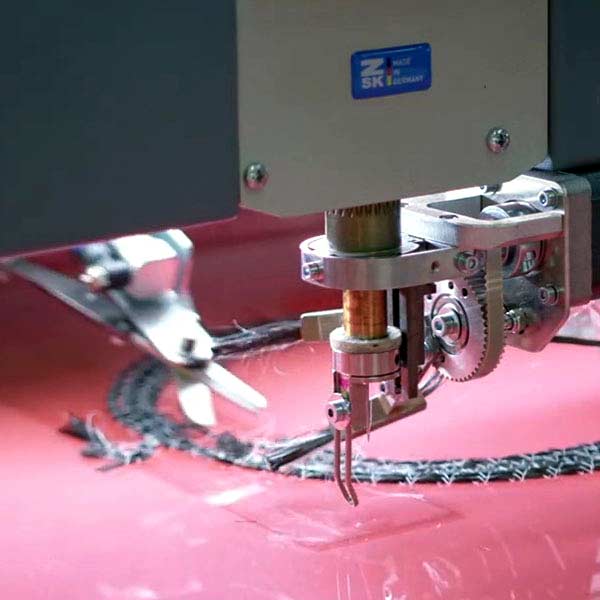

The Outside Laying Motor: Your Performance Pro for Production

Best Workflow – Ideal for High-Efficiency Production

For the Performance Pro

Are you the type who prioritizes maximum efficiency and seamless production? Then the Outside Laying Motor is your **Performance Pro**. It was developed to minimize downtime and simplify handling.

Ideal for Series Production

- **Versatile Material Feed:** Compatible with Single/Twin Fiber/Wire Supply and Active Supply System.

- **Automatic Material Change:** No manual intervention needed – the system changes material automatically and seamlessly.

- **Support for Triple Material Changer:** Enables the use of up to three different materials in one operation.

- **Park Position for Unused Heads:** Prevents collisions and protects your frame when not all heads are operating simultaneously.

- **Integrated Pneumatic Fiber/Wire Cutter:** Automates cutting and saves valuable time.

- **Highest Fiber Laying Speed:** Supports top production speeds for maximum throughput.

- **Extended HV-TFP Compatibility:** Suitable for fiber and wire, with future support for up to three fibers/wires simultaneously.

- **Low Maintenance Effort:** Especially easy access for quick maintenance to minimize downtime.

Important Points to Consider

- **No Small Spools:** This Laying Motor is not designed for processing small spools.

- **No Winding Function:** The special winding function is not available with this type.

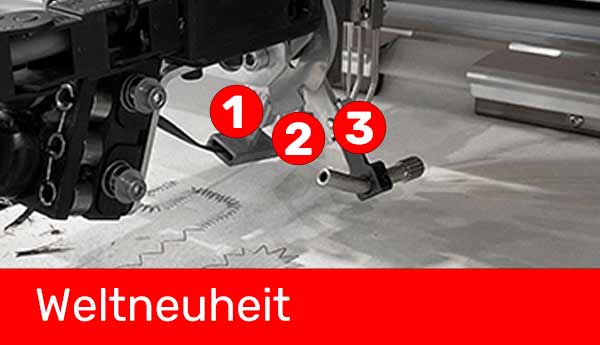

World First: Revolutionary Material Change for TFP and TWP

With the Outside Laying Motor, ZSK introduces a true world first that can revolutionize your production: **automated material change**. It enables seamless integration of TFP and TWP through triple-material integration.

Imagine manufacturing a complex functional component, like the frame of a high-tech drone.

With this technology, the process can **automatically** and without manual interruption switch between:

- **Carbon fiber reinforcement** for maximum structural rigidity

- **Antenna cable** for seamless communication

- **Power cable** for reliable motor operation

This groundbreaking function opens up entirely new possibilities in the production of multi-functional components. It drastically reduces manual intervention, elevates efficiency to a new level, and paves the way for manufacturing the most complex products in a single, automated process.

Conclusion: Which Motor Truly Fits You?

The choice of the right Laying Motor largely depends on your individual goals.

Your Individual Goals

- **Are you the "Inside" Type?** If you're involved in **Research and Development**, value flexibility in smaller batches, and manual steps aren't a hindrance, then the **Inside Laying Motor** is a cost-efficient and precise solution for your prototypes and experiments.

- **Or rather the "Outside" Type?** If you're aiming for **Series Production**, require maximum efficiency and minimal downtime, and want to benefit from automated processes, then the **Outside Laying Motor** with its unique automatic material change function is the strategically sound investment.

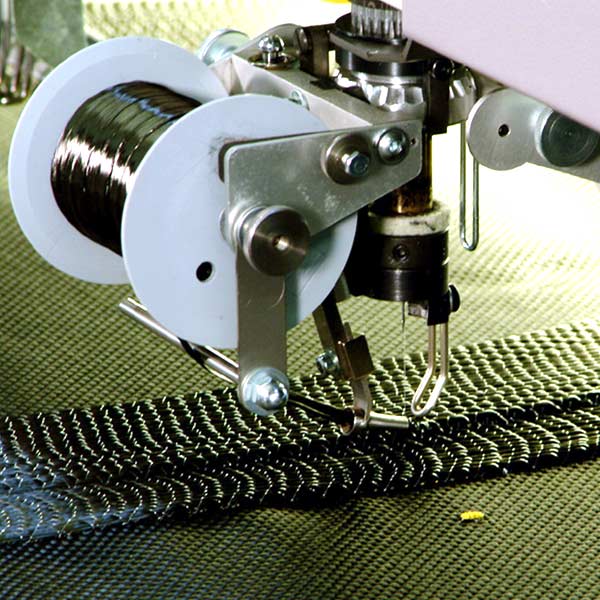

OUR VARIETY OF LEGS

- Suitable for different media and diameters

- Ensure precise positioning of the seam

- Increase stability and quality

Discover all laying solutions for technical applications now!

Let's talk about it!

Not sure which layer motor is best for your project? We understand! Contact our team of experts at ZSK STICKMASCHINEN.

We will be happy to advise you individually and find the perfect solution that fits your workflow exactly.

René Gotolle

ZSK Technical Systems Sales Manager

rene.gotolle____________@zsk.de

Tel: (+49) 151 467 46 582