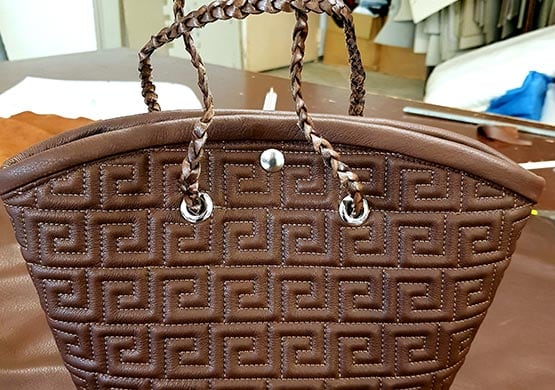

About Leather Embroidery

ZSK embroidery machines are known since decades to be workhorses and very strong and precise on heavy materials. Leather is a material with its variety of thicknesses and densities that can be a more difficult material to embroider. ZSK has invested many efforts during the past three years to increase its capabilities in the field of leather embellishment. The embellishment of leather is found in trim shops, seat manufacturers, leather good companies, shoe manufacturers, fashion ateliers and furniture manufacturers. The capabilities of ZSK include very fine designs, sequins, cording and taping as well as heavy sewing.

Perforation and Quilting

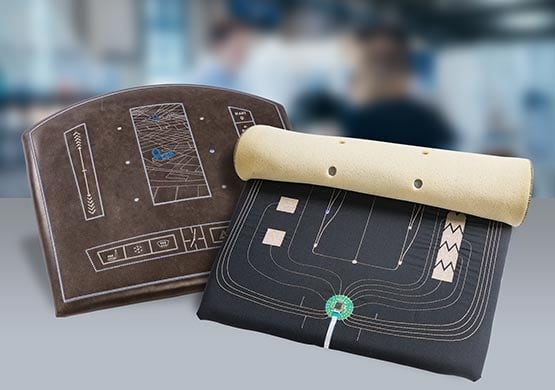

When using sewing machines, the operation is limited to one colour and thickness of yarn. A combination of quilting with delicate designs is not possible. ZSKs technology allows combination of quilting / sewing and embroidery on each embroidery head with a variety of colours by using different needle sizes on the needle bars. ZSK machines can embroider sewing yarns such as AMANN Serafil #10, 15 and 20 without issues. Designers enjoy the capabilities as one part can include a variety of sewing yarn colours and can be combined with logos in one process. The biggest challenge is the perfect combination of sewing, embroidery and perforation. Beside design reasons, there are technical reasons such as airflow why perforation is seeing a growing demand in the seat industry.

Video

This video shows the possibilities of ZSK embroidery machines to create exclusive embroidery designs on leather, Alcantara and other cover materials for different industries such as automotive interior, caravans, aircrafts, super yachts etc.

If you would like to find out more about the possibilities of ZSK embroidery machines, write to us using our contact form.

The ZSK Vision System

The ZSK Vision System recognizes perforation, shapes and colour differences. The EPCwin Digitizing System is used to create an embroidery file and an automation file (ZEPL), which allows the ZSK Vision System to compare location of perforation holes with the engineering file. The embroidery machine can place the embroidery at the suitable position on the material to stay within tolerances. The system is also capable to stretch and shrink designs to compensate for shrinkages and elongation in the leather i.e. after the lamination process. It is important to note that the system cannot compensate for non-linear changes during the perforation or lamination process. If changes are linear or design components do not pass across the entire design, the placement can still allow a successful completion of the design.

Choice of Equipment

ZSK offers an extensive range of possibilities in terms of equipment choices. Applications requiring the ZSK Vision System only work with single head machines, as it is assumed that each work piece is different and behaves different. Otherwise, any quantity of heads can be upgraded to handle thick sewing yarns for upper and bobbin yarns. A speciality of ZSK is the 18 and 24 needle embroidery head. The head allows a wide variety of colours and yarn sizes to be combined in one design. Single Head machines are offered with field dimensions of 500x500mm, 700x700mm, 1.100x700mm or 1.300x1.500mm. For special applications, ZSK can offer field depths of up to 2.000mm and 2.500mm. Special requirements can always be discussed with ZSK and in some cases it might be necessary to design a new machine model to fulfil the purpose. Beyond standard embroidery machines, ZSK offers combination machines with a W-Head (Cording, Coiling and Taping) and K-Head (Moss- and Chain-Stitch) that can be used to embroider leather strings i.e. for the fashion or furniture industry.

Design

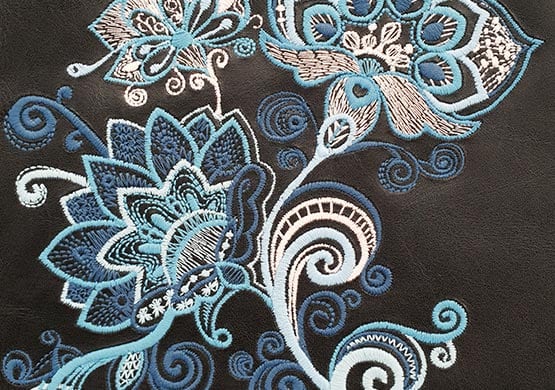

The capability of up to 24 choices per head makes ZSK the leader in terms of design capabilities. In combination with conductive yarns, embroidered leather goods cannot only make a visual impact, but can include smart functionality as well. In 2018 ZSK presented a leather dashboard which controls fully embroidered capacitive sensors.

The choices include:

- Thread Colours

- Thread Sizes (Thin to Thick)

- Thread Types (Embroidery Yarn, Sewing Yarn, Fancy Yarn)

- Cording

- Taping

- Sequins

- Beads

The right Needle

ZSK recommends Groz-Beckert needles for leather applications. ZSK distributes 90 and 110 DH needle for embroidery machines. This needle system is part of the secret of straight sewing lines. This needle allows embroidery of sewing yarn in all directions with straight lines. Design requests might require different looks, where embroidery machine needles do not offer sufficient design choices. For these applications ZSK can offer needle bars that can hold needles for sewing machines. In case of special requirements, it is always worth contacting ZSK to discuss if a specific solution is available.

Customization

In many projects the embroidery machine is only one aspect of the overall project. Customer specific requirements for Health & Safety, production tracking or environment tracking can be of high importance. The ZSK R&D department offers solutions that go well beyond a light barrier. Customized solutions can include light curtains, special table plate designs (incl. entry doors in the table), needle protection, take up lever protection, noise protection, key control of machine, sensors for work environment control (humidity, temperature etc.), operator tracking, production analysis (My.ZSK) and many other features. ZSK is known to analyse specific and unique customer requirements and to design solutions to fulfil the requirements.

Auto Select Bobbin Changer

In 2017 ZSK introduced the Auto Select Bobbin Changer for up to 8 bobbins. The previous generation would replace one bobbin after the other. The Auto Select Bobbin Changer matches the bobbin number with the needle number. This allows matching of upper and bobbin yarn colour and thicknesses. Beyond using different bobbin yarn thicknesses, the bobbins can also have different tensions, which is required when working with thick and thin yarn. The bobbin tension that holds thick yarn is usually higher compared to bobbin tensions for normal embroidery yarn. ZSK offers a variety of bobbin cases with different tension settings. The right choice of the bobbin case will be important to ensure a very good embroidery quality.

Case Study - Rühl Leder

Rühl Leder, a long-established company based in Mülheim an der Ruhr, Germany has been one of ZSK Stickmaschinen’s customers since mid 2018.