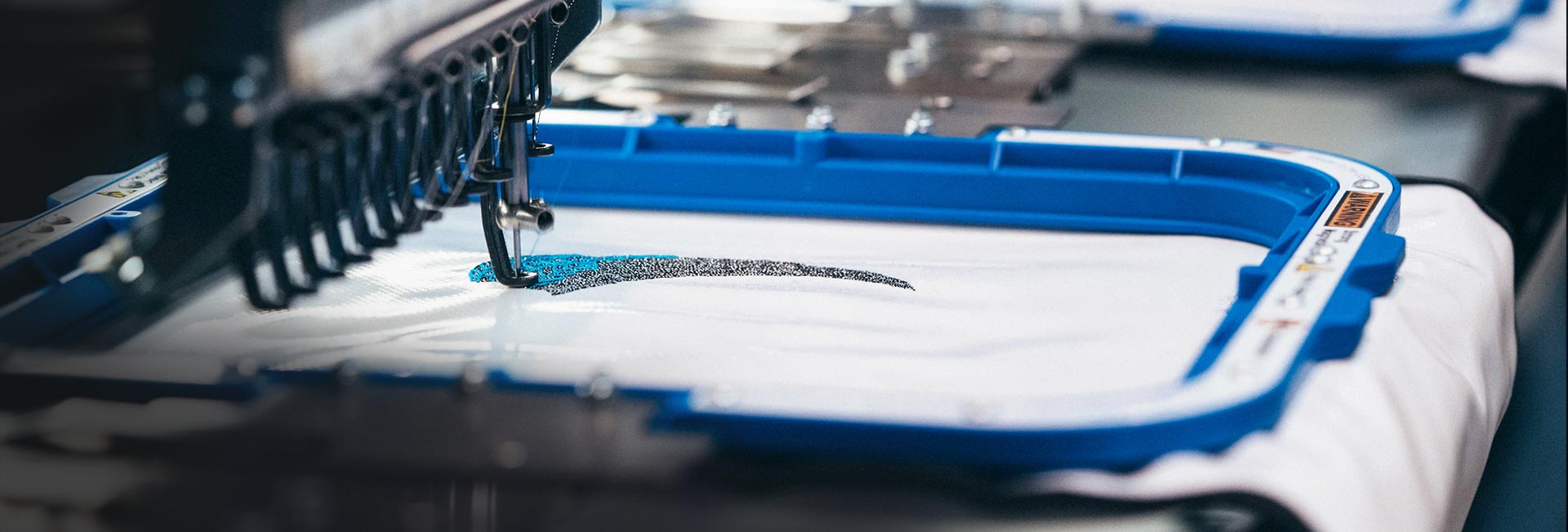

Aligning Print and Embroidery in All-Over Productions

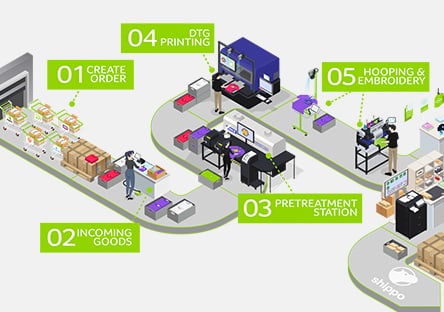

At Heimtextil 2019 in Frankfurt ZSK STICKMASCHINEN and SMAKE have presented the new EPS Project. The system is the solution to solve alignment issues of printed fabrics and embroidery in all-over production.

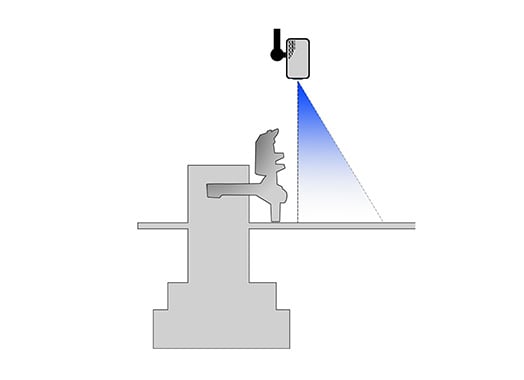

Projectors installed on a bridge over the embroidery machine

EPS Project includes at least two projectors with special lighting (to deal with light and dark fabrics) and a SMAKE control box. The projectors are installed on the outside heads of the embroidery machine. If more than two projectors are installed, they can also be in the center of the machine. The system can project embroidery files and therefore enables the machine operator to fix the fabric in the border frame at the perfect position.

The SMAKE control box can access files from the server via network or files can be placed into the hotfolder of the SMAKE control box.

Different head distance and field depth can be adjusted by changing the distance between projector and fabric

The projectors can be installed either on a bridge going across the machine, or directly on a bar hanging from the roof.

The combination of print and embroidery has grown in popularity during the last years and the perfect placement of the design has always been a time consuming activity. The EPS Projector reduces the setup time and therefore increases the productivity of the machine and allows a higher precision in design placement.

CHALLENGER

Our flat bed embroidery machines are the ideal means of production with which you can meet even the highest quality requirements of your customers.

Smake®

EPS stands for “Easy Positioning System”. The patented Smake EPS series includes different finishing areas and applications on and with different machines.