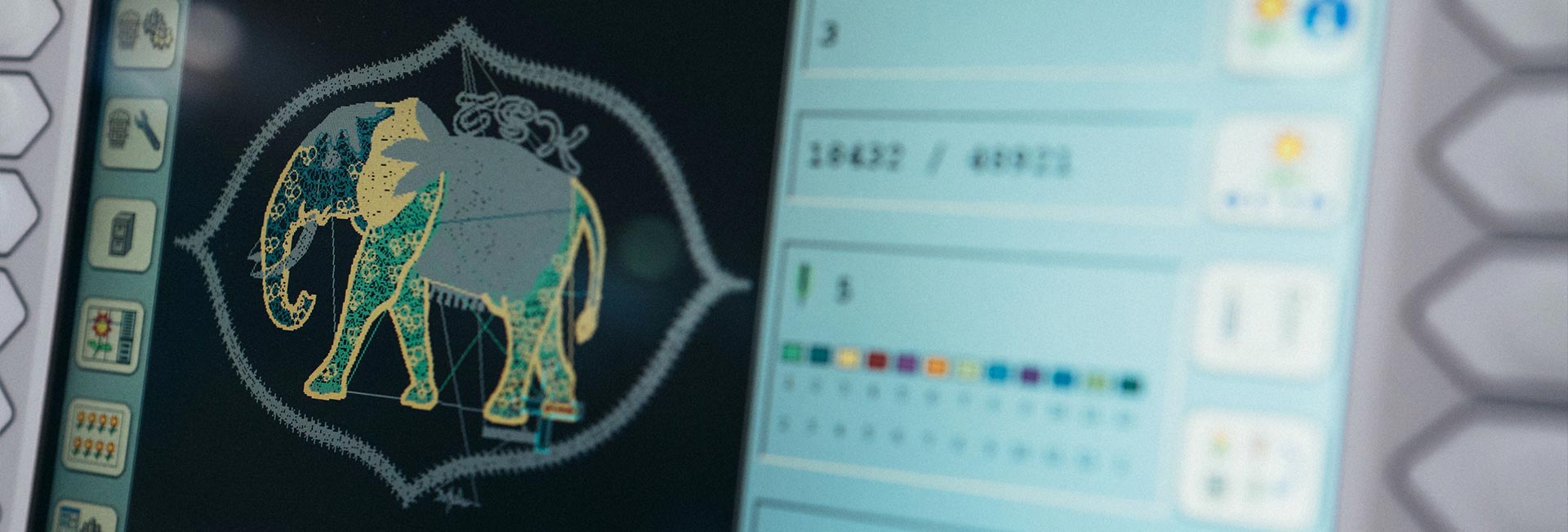

Embroidery machines are operated by embroidery files that come in a variety of formats. The T8 controller can handle the following formats: DSB, Uxx, PEC, PES, DSG, EXP, KSM, TBF, DST, EXX, DSZ, FXX and ZSK. The most well-known code in the embroidery industry is the DST code. It is the most basic code, can be created by any digitizing system and can be read by probably every embroidery machine that is produced today.

The DST format comes from the times of paper punchcards. It is a proprietary format that only contains stitch commands. The files have a maximum jump length of 121, the files do not contain colour information, no vectors and no thumbnails. Beyond the simplicity and limitations of the code itself, it brings actual disadvantages to its users.

Das Laden einer DST Datei in Ihre Stickmaschinen dauert viel länger als bei einem ZSK-Format, und die Fehlerwahrscheinlichkeit für den Benutzer ist sehr hoch. Eine allgemeine Annahme ist, dass das Laden einer DST-Datei 20 Sekunden länger dauert als das Laden einer ZSK-Datei, und bei einem Durchschnitt von 10 Motiven pro Tag würde dies einen Produktionsausfall von 200 Sekunden pro Tag bedeuten. Am Ende eines Jahres sind dies ca. 14 Stunden verschwendete Zeit auf der Maschinensteuerung.

We highly recommend ZSK machine users to digitize in ZSK format or to request external digitizers to supply the embroidery files in this format.

Customers in the fashion industry or technical embroidery can benefit from further benefits. Not only a lot of commands for accessories (i.e. twin sequin device) can be stored in the file format, but also settings for the W-head and K-head can be saved and stored in each design and even be adjusted within a design.

Carl – The customer magazine

In our customer magazine we are publishing updates about ZSK STICKMASCHINEN, our embroidery machines and accessories.

TOP 100

In 2017, ZSK Stickmaschinen GmbH was honored as one of Germany's most innovative mid-sized companies by TOP 100.