A highly efficient process

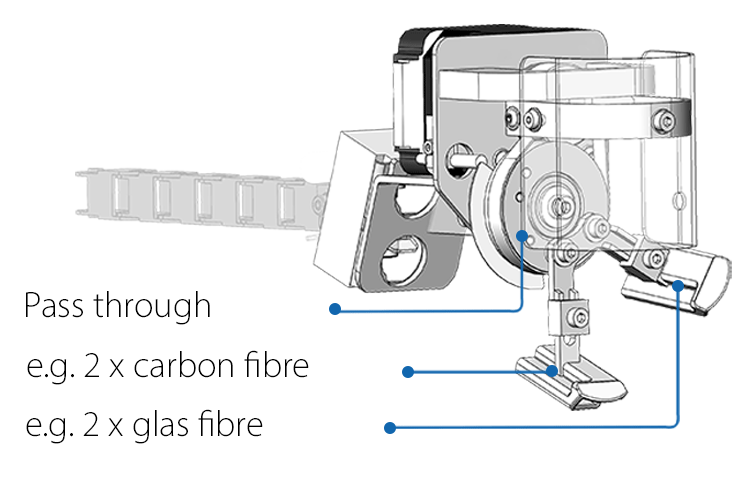

Switching between fibre strands / media

The process offers numerous advantages compared to conventional methods.

- ZSK offers a patented method for automatic switching up to 4 fibre strands, which enables independent or parallel laying of fibres.

- Limitless selection of fibre type: carbon fibre, glass fibre, mineral fibre, natural fibre, thermoplastic fibre, commingled fibre.

- Automatic alternation enables integration of wires or fibre-optic cables.

Produce more efficiently with ZSK innovations

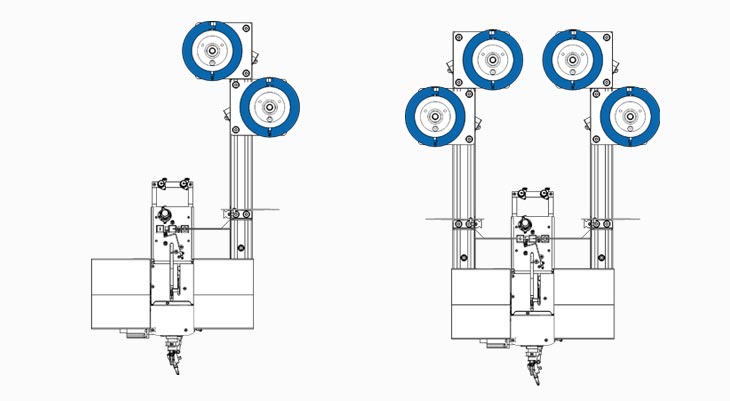

200% increase in volume

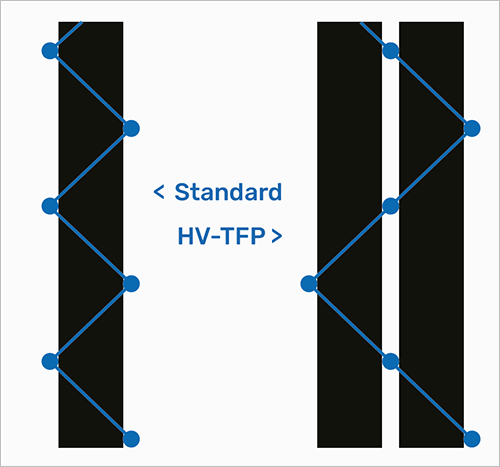

High Volume -TFP (HV-TFP)

- ZSK, in collaboration with Nobrak SAS, has developed a patented process for the parallel placement of 2 or more fiber strands.

- The innovation doubles the placement volume of fiber strands, leading to a significant increase in productivity for mass production applications

75% increase in output

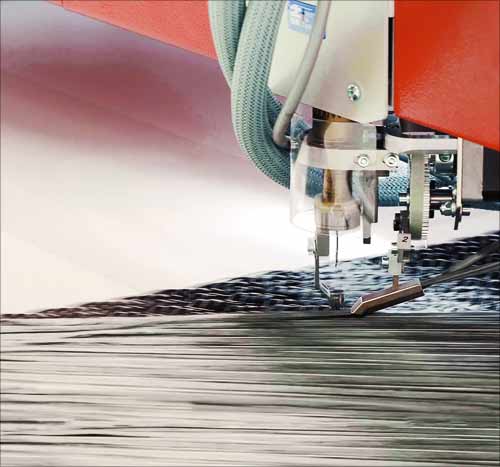

Fast Fibre Laying

- Patented technology enables high-speed laying of fiber strands without stitches.

- Up to 8 layers can be laid at various angles; the last layer is fixed with continuous stitches,securing previous layers.

300% increase in performance

Combination of HV-TFP and Fast Fiber Laying

- The combination of HV-TFP and Fast Fiber Laying achieves performance increases of up to 300% compared to the conventional TFP technology.

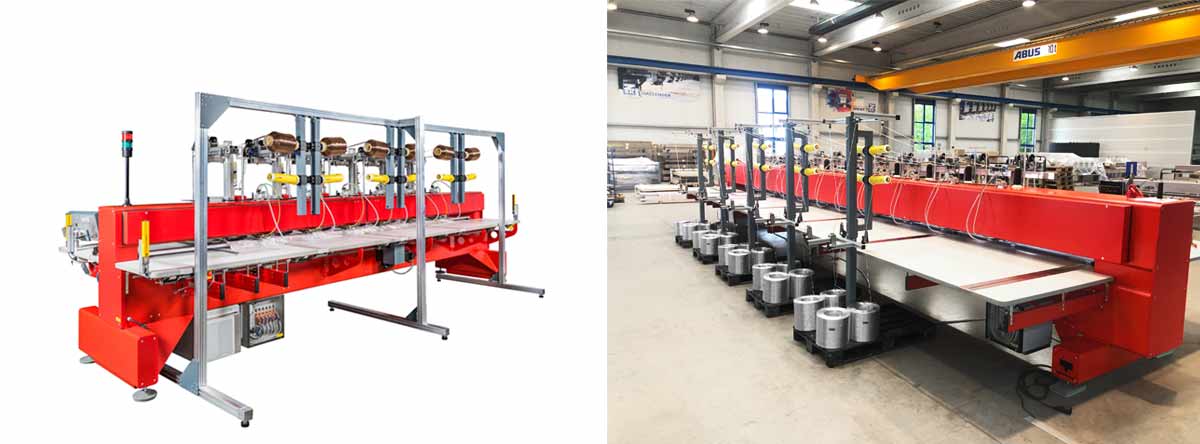

Media supply optimised for industrial requirements

Media Supply

- Up to 4 fiber strands per head can be fed via a rack from behind the machine.

- Ergonomic access for changing heavy fiber rolls.

- Active fiber take-off.

- Automatic material cutter.

- End-of-fiber detection.